The concept of appealing packaging, in a way, has varied.

In today’s times, it is not just about eye-catching but also credibility, as the fact that customers could intuitively see the product without unpacking before any purchase would draw more attention and sales drive. See-through design, therefore, has been put into consideration as one of the focused directions for packaging R&D.

And it might seem not so complicated until UV light transmittance comes in the way.

Let’s take a deep dive into how Toyo Ink solves the matter of maintaining still the packaging’s transparent appearance while avoiding the UV-ray affection toward the contents inside, with one of its latest innovative solutions, Z254 Clear UV NT.

(*) Manufactured by Toyo Ink Japan, a company of the Toyo Ink Group.

Imported and distributed to the Vietnamese market by Toyo Ink Vietnam.

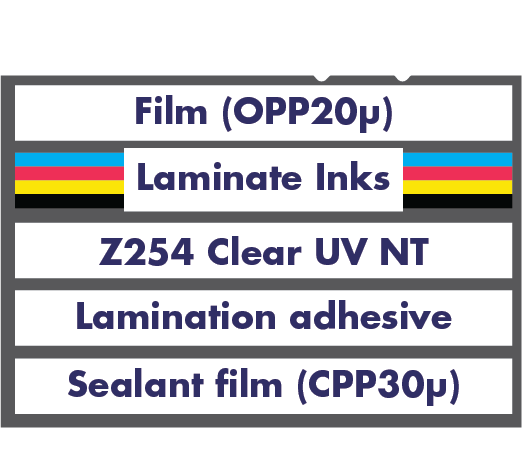

Z254 Clear UV NT is a non-toluene/ non-MEK functional coating agent for reverse gravure printing.

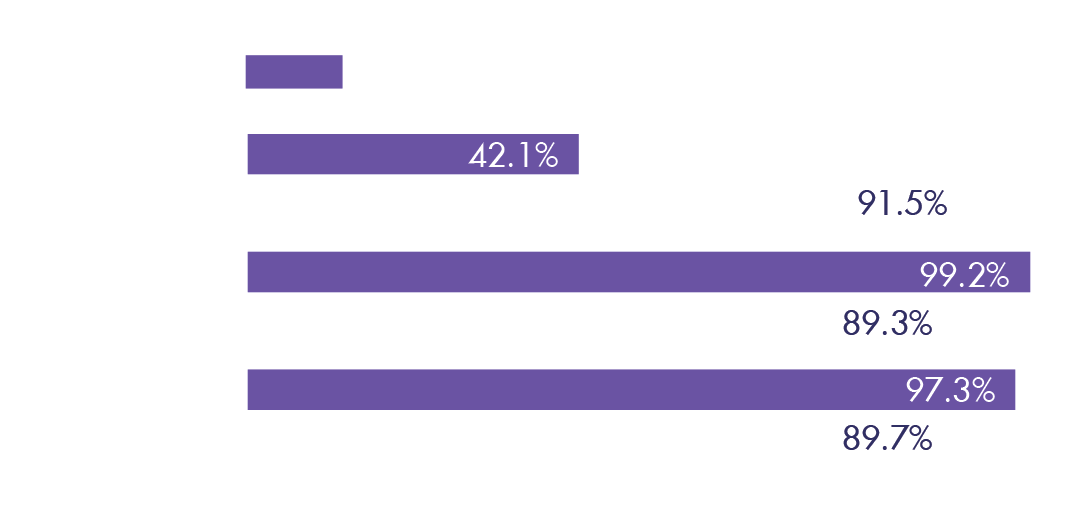

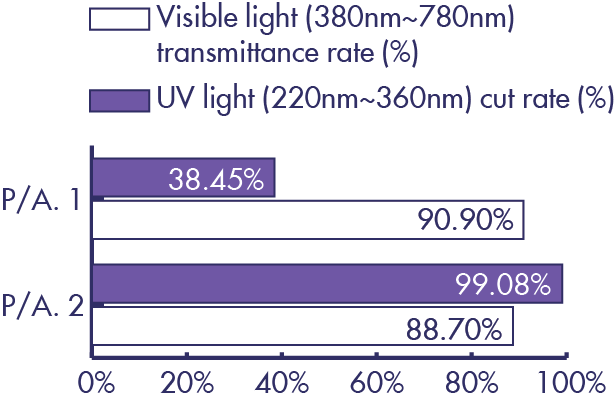

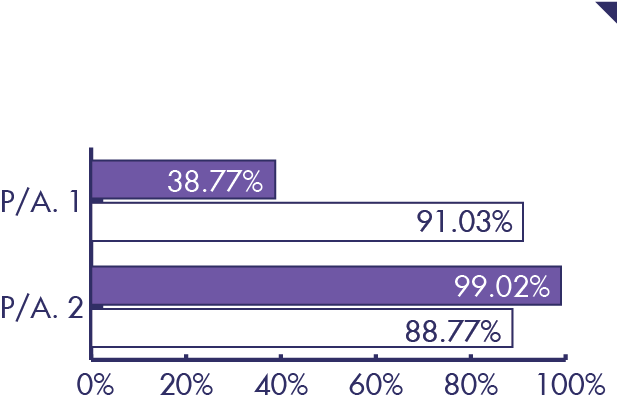

It helps cut almost all the ultraviolet rays while allowing high visible light transmittance, achieving high UV protection at a lower film thickness, compared to other conventional structures.

Features

High transparency

Non Toluene

Non MEK

Supplementary Information

A recent laboratory test shows that Z254 Clear UV NT has the potential for application in surface printing.

However, an additional layer of coating is required to protect Z254 from being rubbed off and help it perform at its best.

(5N×100 times) – Average of N3

(*) Structure

Option 1: OPP / VN201 Clear NT Varnish (175L,35μ)

Option 2: OPP / Z254 Clear UV NT (200L,20μ) / VN201 Clear NT Varnish (175L,35μ)

For more details on the hazard identification applied to this product, please check its respective Safety Data Sheet.

Featured images by:

@rawpixel.com / @clyde_he

Vietnamese

Vietnamese