What is GLYMO?

GLYMO is an epoxy silane, precisely known as “3-Glycidoxypropyltrimethoxysilane”. Throughout the history of lamination, this chemical compound has been utilized under the concept of adhesion promoters, giving an essential boost to the bonding strength, which conventionally gets affected by moisture, heat, and properties of substrates to adhere.

Its application in that sense is also quite common in the food packing industry where several of the most demanding packaging sorts exist, like pouches that could be boiled, retorted, or used in a microwave.

Why GLYMO-free?

For a long time, GLYMO had performed as an FCM (food contact material), only until its potential genotoxicity(*) was questioned in the EU market, starting with a safety assessment(1) by EFSA (the European Food Safety Authority) in late 2017. FEICA (the Association of the European Adhesive & Sealant Industry) thereafter through a statement(2) around July 2019, recommended its members, including adhesive firms to substitute GLYMO by the end of 2020 in applications intended for food contact (i.e. food packaging) and assist customers in implementing alternative solutions for food contact applications.

(1) EFSA’s safety assessment of GLYMO, for use in food contact materials

(2) FEICA recommendation to substitute GLYMO

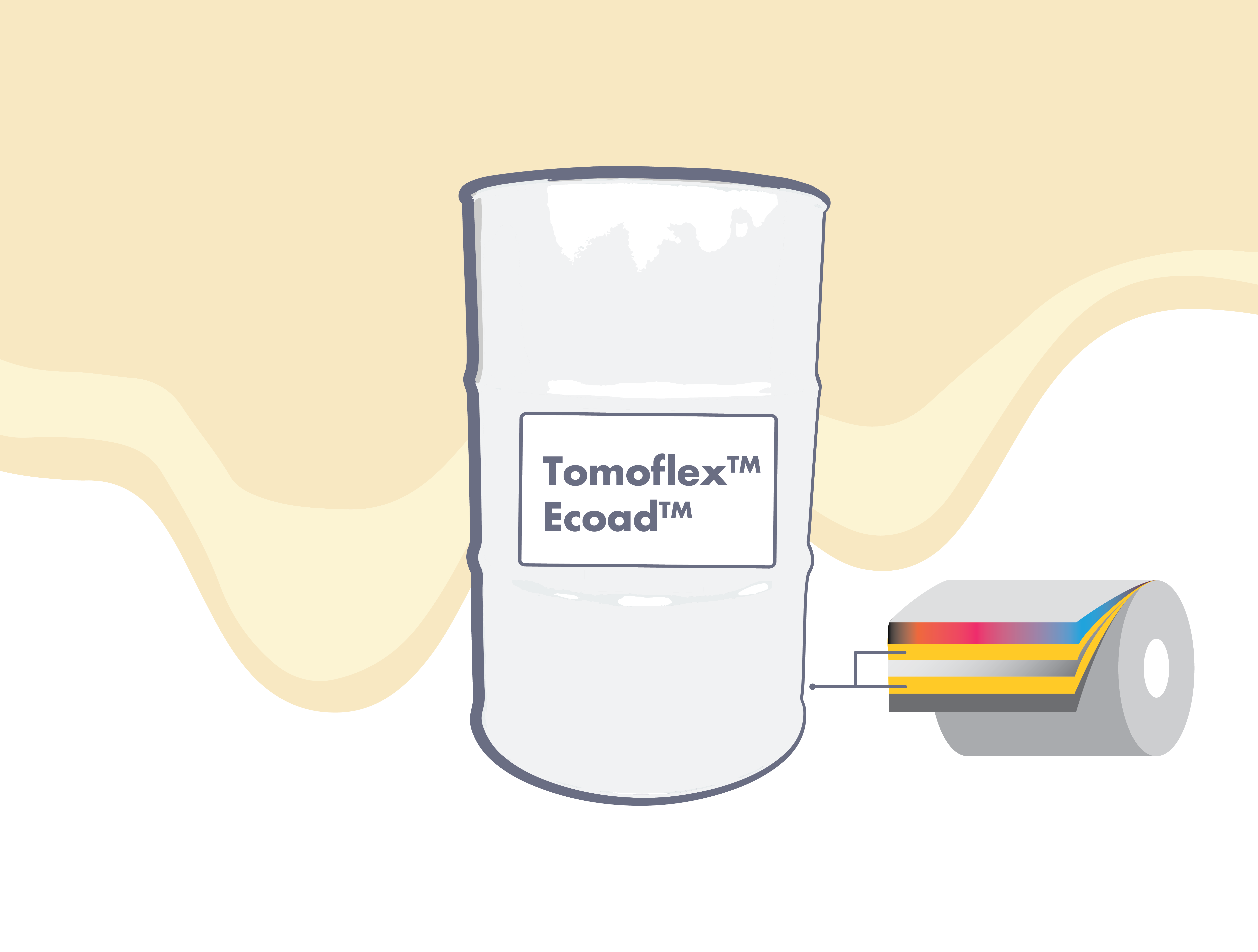

In the widespread GLYMO-free movement, Toyo-Morton also does not stay still but concentrates on developing its own GLYMO-free lamination adhesive variations under two core brands Tomoflex™ and Ecoad™, which at different aspects we shall now dive into.

(*) Manufactured by Toyo-Morton, an affiliated company of the Toyo Ink Group.

Imported and distributed to the Vietnamese market by Toyo Ink Vietnam.

Performance Grade

General Performance (GP)

Looking for lamination adhesives applicable to a wide range of non-boil and non-retort sorts of packaging? We got you covered, from snack bags to sachets for seasonings, shampoos, and detergents.

Ecoad™

EA-N6000/EA-N5510

Polyester (resin)

Solvent-free

Good appearance and high-speed coating on PET/VM-film

Ecoad™

EA-N6008/EA-N5510

Polyester (resin)

Solvent-free

Good appearance on VM structure

Applicable for boil pouch

Tomoflex™

TM-3040-1/CAT-1040

Polyether (resin)

Dilute with EA

High solid coating

Medium Performance (MP)

Packagings that survive through demanding storage and using requirements like being boilable or chemical resistance also require a level up in the performance of lamination adhesive and we have numerous series to serve just that.

Ecoad™

EA-N6008/EA-N5774

Polyester (resin)

Solvent-free

Good BS&HS

Good appearance on PET/VM-film

Tomoflex™

TM-2470/CAT-10

Polyester (resin)

Dilute with EA

High solid coating

Applicable for a wide range of packaging types (Snack, Boiling, Refill & AL foil)

High Performance (HP)

To be retortable, packagings should be equipped with top-performance-oriented properties and we so understood the assignment that the below options got developed.

Tomoflex™

TM-2380/CAT-10

Urethane (resin)

Dilute with EA

Aromatic (hardener)

Good adhesion to ink

Good heat resistance

For outer Aluminum layers

Tomoflex™

TM-2300/CAT-1600

Urethane (resin)

Dilute with EA

Aliphatic (hardener)

For inner/outer Aluminum layers

FDA compliance

In the food packaging segment, compliance with related regulations like from FDA has become essential for packaging manufacturers to win customers, and we are here to help.

FDA175.105

Tomoflex™

TM-3040-1/CAT-1040

TM-2470/CAT-10

TM-2380/CAT-10

TM-2300/CAT-1600

Ecoad™

EA-N6000/EA-N5510

EA-N6008/EA-N5510

EA-N6008/EA-N5774

FDA177.1390

Tomoflex™

TM-2300/CAT-1600

For more details on the hazard identification applied to these products, please check its respective Safety Data Sheet.

Featured images by:

@8photo / @jannoon028 / @kjpargeter/ @starline

Vietnamese

Vietnamese