Nowadays flexible packaging has reached the diversity that we probably could never think of when it first appeared.

That places the use of a single material on the verge of being unable to bring demanded properties to the table. To such concerns, compositing two or more material layers perhaps is the finest solution to take.

Lamination, in that sense, has gradually claimed its irreplaceable presence and position in pre-printing processes of material handling. Lamination adhesives have also evolved, enabling all sorts of possible features and configurations that power manufacturing capabilities while getting desired productivity and performance pulled off.

Let’s get to know Tomoflex™ and Ecoad™, two representative series for lamination adhesives from Toyo-Morton while taking a look at some of usual matters with lamination in flexible packaging production.

(*) Manufactured by Toyo-Morton, an affiliated company of the Toyo Ink Group.

Imported and distributed to the Vietnamese market by Toyo Ink Vietnam.

Performance Grade

General Performance (GP)

Looking for lamination adhesives applicable to a wide range of non-boil and non-retort sorts of packaging? We got you covered, from snack bags to sachets for seasonings, shampoos, and detergents.

Ecoad™

EA-N6000/EA-N5510

Polyester (resin)

Solvent-free

Good appearance and high-speed coating on PET/VM-film

Ecoad™

EA-N6008/EA-N5510

Polyester (resin)

Solvent-free

Good appearance on VM structure

Applicable for boil or semi-retort pouch

Tomoflex™

TM-319/CAT-11B

Polyether (resin)

Dilute with EA

Good wettability

Applicable up to boil packaging

Tomoflex™

TM-3040-1/CAT-1040

Polyether (resin)

Dilute with EA

High solid coating

Medium Performance (MP)

Packagings that survive through demanding storage and using requirements like being boilable or chemical resistance also require a level up in the performance of lamination adhesive and we have numerous series to serve just that.

Ecoad™

EA-N6008/EA-N5774

Polyester (resin)

Solvent-free

Good BS&HS

Good appearance on PET/VM-film

Tomoflex™

TM-215/CAT-10

Polyester (resin)

Dilute with MEK

Good chemical resistance

Applicable for a wide range of packaging types (Boiling, Refill & AL foil)

Tomoflex™

TM-2710/CAT-10

Polyester (resin)

Dilute with EA

High solid coating

Good acid contents resistance

Tomoflex™

TM-2419/CAT-10

Polyester (resin)

Dilute with EA

Applicable for a wide range of packaging types (Boiling, Refill & AL foil)

High Performance (HP)

To be retortable, packagings should be equipped with top-performance-oriented properties and we so understood the assignment that the below options got developed.

Tomoflex™

TM-585-60M/CAT-10

Urethane (resin)

Dilute with EA

Aromatic (hardener)

Good adhesion to ink

Good heat resistance

For outer Aluminum layers

Tomoflex™

TM-250HV/CAT-1600

Urethane (resin)

Dilute with EA

Aliphatic (hardener)

For inner/outer Aluminum layers

High Solid Coating

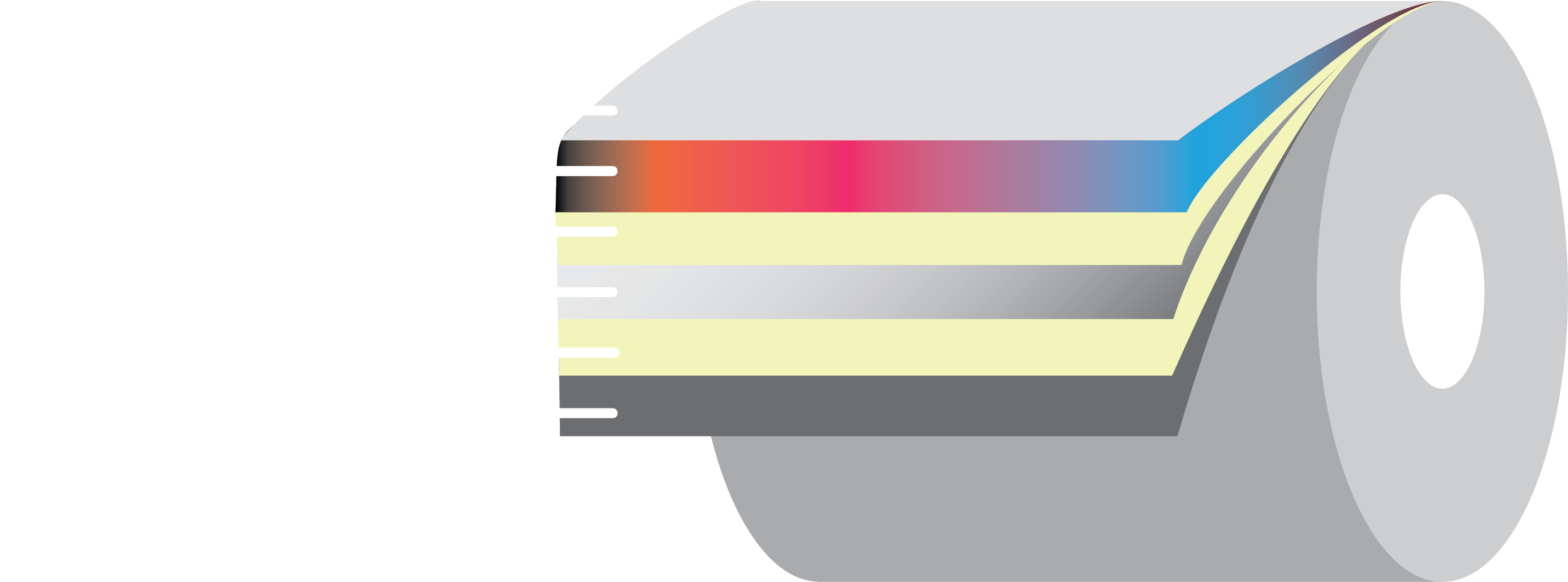

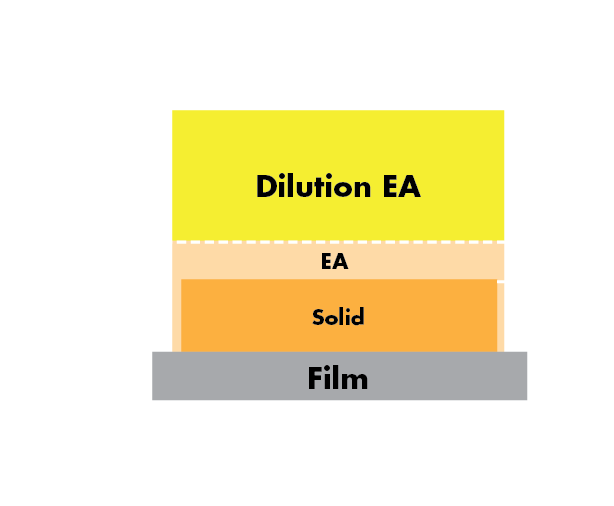

VWith our latest technology, lamination adhesives are now able to perform at a higher solids content, meaning less Ethyl Acetate (EA) to use for dilution.

Figure 2. How high solid coating helps save the EA amount used in dilution.

Tomoflex™

TM-3040-1/CAT-1040

General performance

Tomoflex™

TM-2710/CAT-10

Medium performance

FDA Compliance

In the food packaging segment, compliance with related regulations like from FDA has become essential for packaging manufacturers to win customers, and we are here to help.

FDA175.105

Tomoflex™

TM-319/CAT-11B

TM-3040-1/CAT-1040

TM-215/CAT-10

TM-2710/CAT-10

TM-2419/CAT-10

TM-585-60M/CAT-10

TM-250HV/CAT-1600

Ecoad™

EA-N6000/EA-N5510

EA-N6008/EA-N5510

EA-N6008/EA-N5774

FDA177.1390

Tomoflex™

TM-250HV/CAT-1600

For more details on the hazard identification applied to these products, please check its respective Safety Data Sheet.

Featured images by:

@8photo / @jannoon028 / @macrovector/ @freepik 1–2–3

Vietnamese

Vietnamese