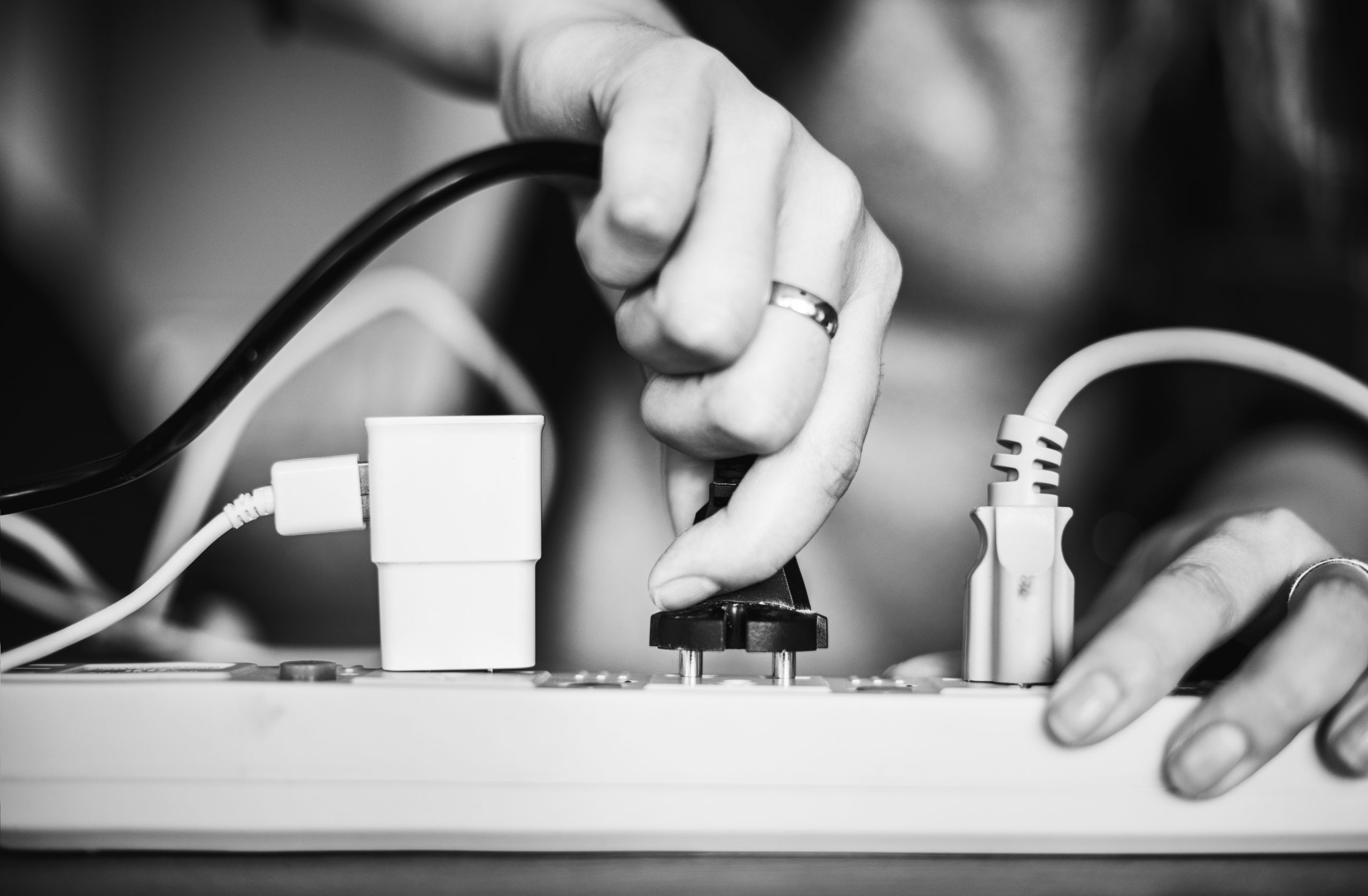

If today’s essentials get listed, electricity is no doubt one of the firsts.

But we are probably mentioning the electric current, generated for operating any kinds of electric devices and machines. There is, on the other hand, another type that results from an imbalance of electric charges occurring within or on the surface of a material, called static electricity. As the name suggests, it stays in one place and remains there until being able to move away by means of an electric current or electrical discharge.

Even though modern scientists have found a number of benefits of static electricity and successfully applied those in how devices like printers, photocopiers, paint sprayers, or air purifiers function, it still in most cases causes troubles, damages, or even dangers (Figures 1).

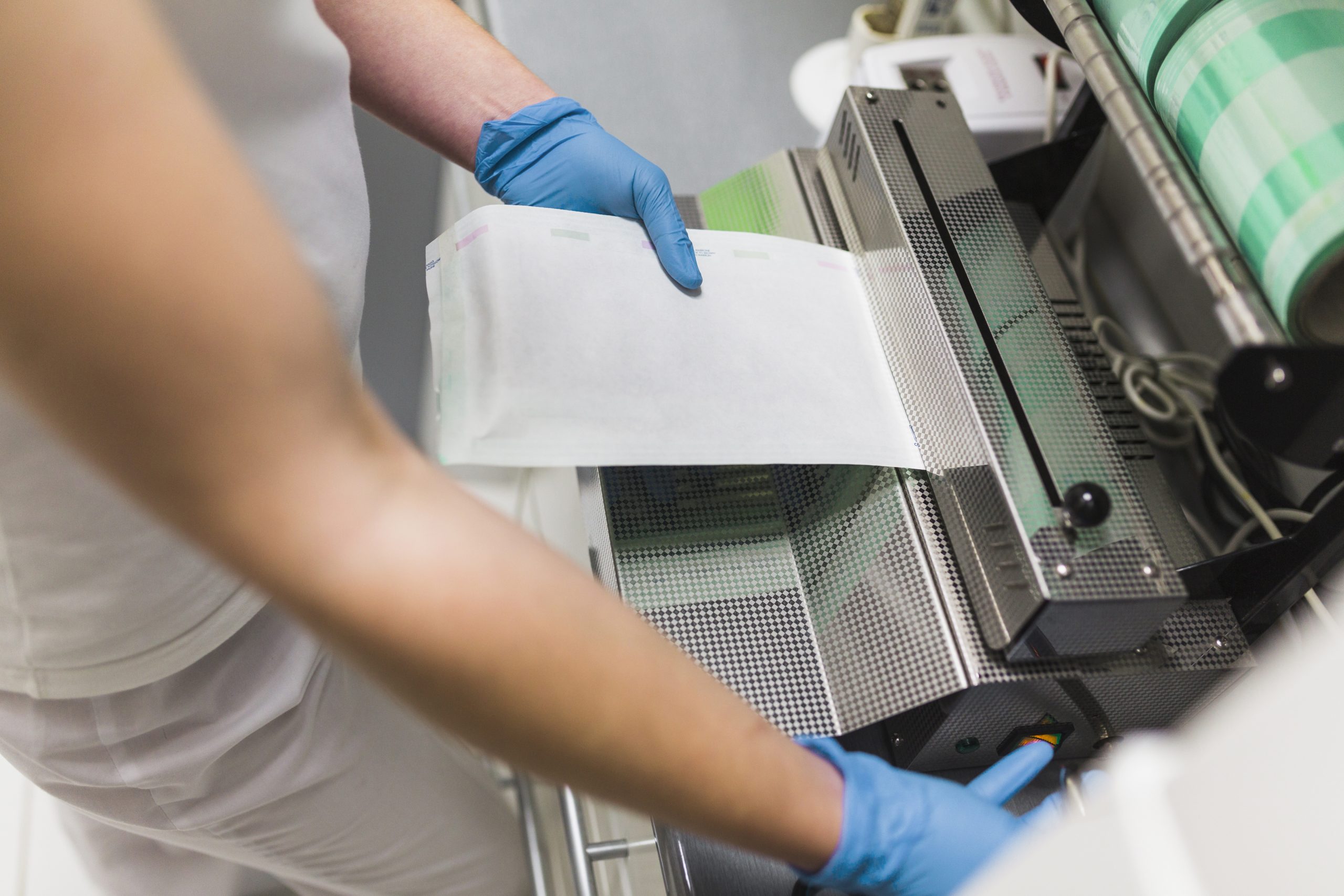

Industry-wise, static electricity affects countless fields, including packaging production.

For instance with flexible packaging and the core material being plastic film, which essentially is an insulator, here comes the phenomenon of the films building up a static charge and causing small particles to adhere to packaging or even the goods inside. That does nothing but create numerous problems for manufacturers like compromised heat sealing ability or contamination during packing and labeling processes, hence the unforeseen downgrading productivity.

There have been several approaches and even solutions to static prevention around the world and at Toyo Ink, we merely cannot bear staying irrelevant. Let’s explore the Z182 E-TOS S Varnish to have a better vision of how Toyo Ink has integrated the antistatic feature into its new line of coating varnish.

(*) Manufactured by Toyo Ink Japan, a company of the Toyo Ink Group.

Imported and distributed to the Vietnamese market by Toyo Ink Vietnam.

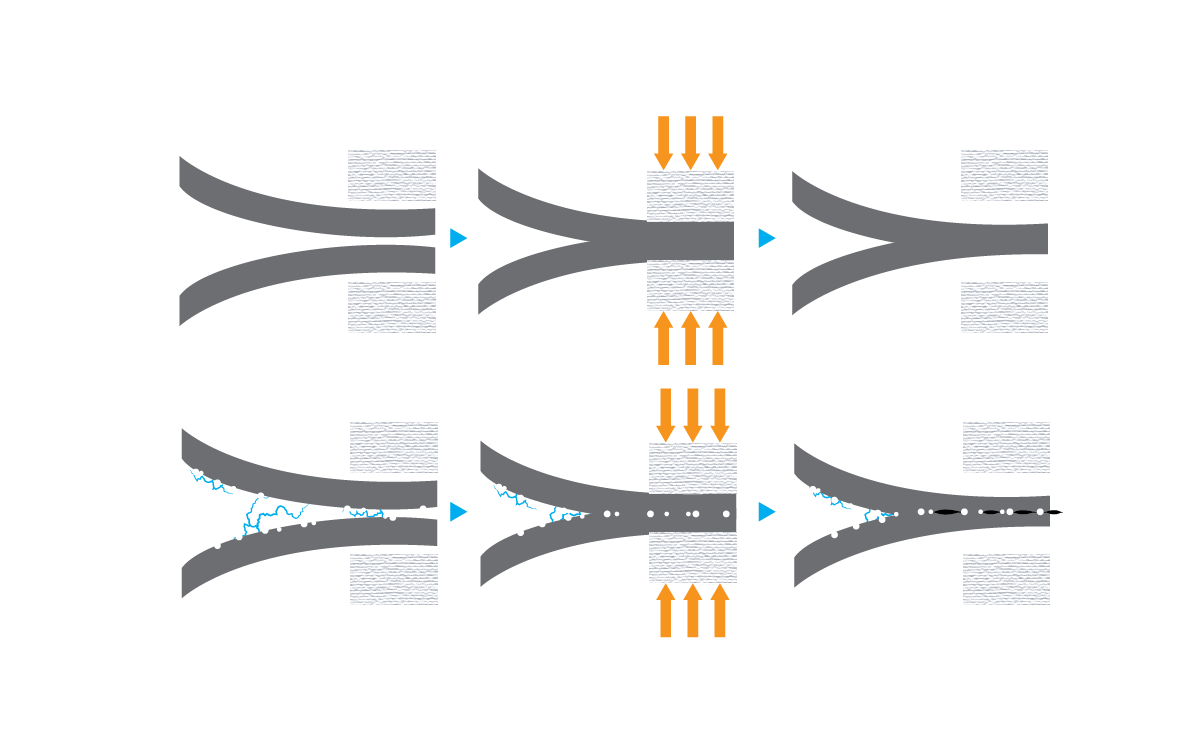

Z182 E-TOS S Varnish is a unique coating varnish that helps prevent and reduce the static charge on plastic film by performing the conductive functionality through a surface coating layer (*) on top of it.

Features

Non-toluene

Clear appearance

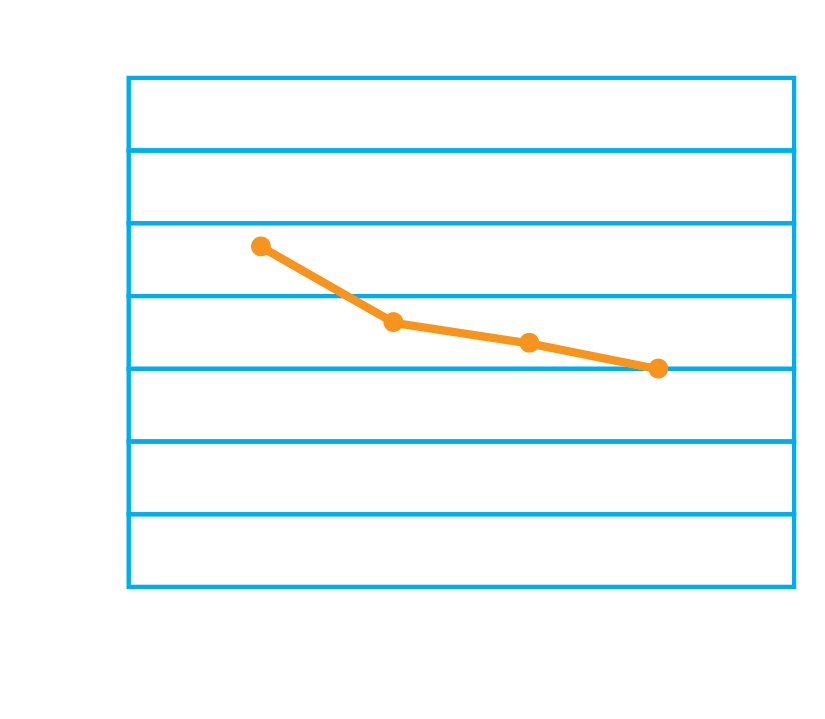

109-1011Ω/□ (Surface resistance)

Good adhesion for PET, OPP, PE

(*) A coating weight of 1µm, applied to the surface of the film (dry) is recommended for well-performed anti-static function.

Applications

Flexible packaging

Electronic equipments & components

Interior decoration

For more details on the hazard identification applied to this product, please check its respective Safety Data Sheet.

Featured images by:

@aopsan / @Racool_studio / @rawpixel.com 1–2 / @freepik

Vietnamese

Vietnamese